Metal Fabrication Capabilities that Exceed Customers' Expectations

Millwood Metalworks offers more than 100 years of combined metal fabrication experience across all areas.

Recognized as an industry expert in custom metal fabrication, Millwood Metalworks has fine-tuned capabilities to effectively complete any job in a timely manner. Our shop provides a number of different processes fabrication process to exceed your expectations — CNC machining, precision plasma cutting, AWS certified welding, and more.

AWS Certified Welding

- MIG — TIG — SMAW

- Large and Small Weldments

- 7 Boom Welders with Miller Axcess 450

- Robotic Welder

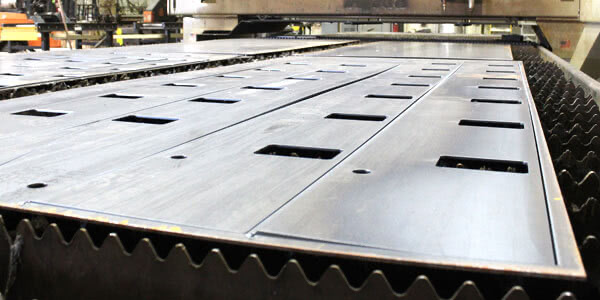

Plasma & Flame Cutting

- 400 Amp HyDefinition Plasma Cutting with True Hole Technology

- Nesting

Lifting / Hoisting

- 20' High 10 Ton Overhead Crane

- (6) 14' High Jib Cranes with 2 Ton Hoist

- 8,000 lb. and 10,000 lb. Fork Lift

- 30' High Ceiling Clearance to Work on Large Projects

Forming, Cutting, Drilling

- 12' CNC Programmable Press Brake - 250 Ton

- 14’ CNC Programmable Press Brake - 600 Ton

- 51 Ton Ironworker

- Punching and Drilling

- Magnetic Base Drills

- 12' x 3/8" Shear

- Band Saw Cutting

Metal Capabilities

- Carbon

- Alloy Steels

- Stainless Steel

- Aluminum

Transportation

Millwood Metalworks maintains long standing relationships with leading cross-country freight haulers to efficiently ship your fabricated pieces when and where you need them.

Our Work Covers Various Industries

Throughout the past decades, Millwood Metalworks has successfully completed metal fabrication and welding jobs for a growing list of clients in a range of industries. Our services have been used to fabricate specialty projects and large production runs, including but not limited to:

- Evap-Condenser Frames

- Industrial Test Equipment Frames

- Stage Handling Equipment

- Dip Tank Lifters

- Bulk Bag Handling Frames

- Stair Towers

- Skid Loader Attachments

- Equipment Support Frames

- Turbine Embed Rings

- Turbine Template Rings

- Turbine Concrete Forms

- OEM Parts

For additional information regarding our shop processes, project estimates, and questions contact Tim Burg.